What’s His Major? Genetics, Cotton and Entrepreneurship

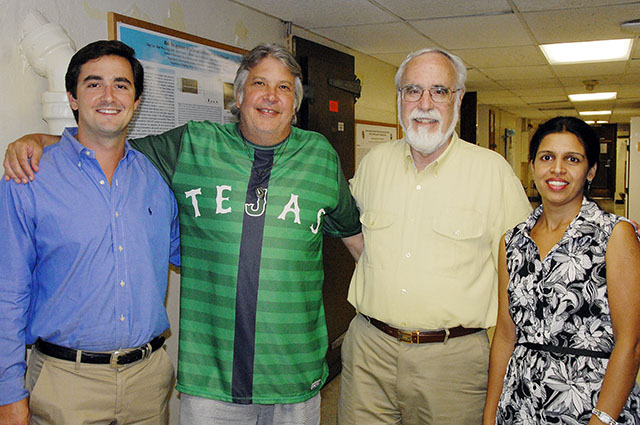

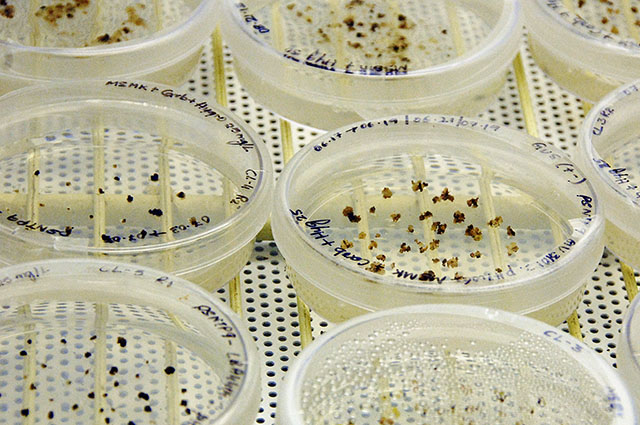

UT researchers and a young entrepreneur are trying to produce cotton with longer and stronger fibers. Early in the genetic modification process, cotton cells are kept alive in culture, where they form embryos. Photo by Oscar Ricardo Silva.

By Ian Floyd

For Reporting Texas

The U.S. cotton industry generates $25 billion in products and services annually, and Texas farmers produce about 35 percent of the cotton crop. Imagine owning exclusive rights to seeds that yield up to 40 percent longer and thicker cotton. Length and strength are cotton’s two most commercially valuable qualities.

Simon Hiebert, 23, thinks he owns those rights.

Hiebert, a May graduate of the University of Texas at Austin, is betting that genetically manipulated cotton plants, now under development by his former biology instructor in a UT lab, will render extra-long cotton fibers and other valuable attributes. CottonGen, the company Hiebert created, will attempt to commercialize the transgenic seeds.

If he is right, CottonGen could bring sweeping change to the agriculture industry and make a killing in the process.

If he is wrong, more than two years’ worth of work and an undisclosed “serious chunk” of investment money will go the way of many a startup effort.

“Here we are with this much invested in terms of time, money and effort,” Hiebert said in an interview. “This could be a huge deal. It would kind of eat at us all to not do our best to move it forward.”

Farmers have used genetically manipulated crops since 1996. The U.S. farms 170.5 million acres, or 43 percent, of the annual world production of genetically manipulated crops, according a 2011 study by Service for the Acquisition of Agri-Biotech Applications, an international nonprofit that supports crop bioengineering.

Stanley Roux, one of UT’s most accomplished plant biologists, discovered an enzyme that controls the concentration of a growth regulator – extracellular nucleotides — in plants. His research showed that by applying different concentrations of extracellular nucleotides, producers could promote or inhibit the growth of stems, roots, pollen tubes, cotton fibers and other plant cells and tissues.

For the discovery to be a commercialization candidate, those growth-controlling properties must be transferred to seeds of an agriculturally important plant. Roux tested this concept on Arabidopsis, a plant that molecular biologists commonly use to test their ideas, by manipulating the plant’s genes to control the enzyme that regulates plant growth.

The transgenic Arabidopsis plants showed signs of increased growth and other valuable properties, and now Roux’s lab is trying to transform the genes of cotton. Whether this effort will pay dividends depends on whether genetic transformation increases the growth of cotton.

According to Roux, the manipulation of genes could result in any number of outcomes: increased fiber length, thickness or strength; faster rates of growth; larger boll size; resistance to heat stress; or more efficient phosphate uptake, allowing better fertilizer utilization. Some of these traits could be commercialized. On the other hand, the transformation could result in no significant change, always a risk in novel research.

The cotton plants are being cultivated in growth chambers. In October, the baby plants will be moved to the greenhouse, where the growth of the mutated cotton will be compared with that of unaltered cotton growing alongside.

“We will be looking at the offspring and testing them at various stages of development,” Roux said in an interview. “We will be characterizing what are its commercially valuable properties.”

Hiebert stumbled upon Roux’s lab four years ago after joining the Freshman Research Initiative, a UT program that places undergraduates with research programs across the university.

As a young, undeclared major in liberal arts, Hiebert was intrigued by the idea of manipulating the growth of plants.

“Right from the get-go, I had this idea in the back of my head that this is really cool,” Hiebert said. “We are kind of fiddling with the way that plants grow and mature.”

After two years and one summer in Roux’s lab, the excitement of scientific experimentation made Hiebert want to pursue a science degree. However, he realized that his good-but-not-perfect grades weren’t up to par with that of the competitive sciences.

By his third year, he switched his major to government and joined the innovation, creativity and entrepreneurship arm of UT’s Bridging Disciplines Program. His first course in the program was Innovation and Entrepreneurship, taught by the charismatic John S. Butler, director of the Innovation, Creativity, Capital Institute, or IC2, the storied UT entrepreneurial wealth-creation think tank.

“He brought this whole idea of bringing an idea from the lab to the market to life for me,” Hiebert said. “That was that. One day I was sitting in class and said, ‘Holy moly, I need to go back to Dr. Roux’s lab.’”

After visiting the lab, Hiebert decided to commercialize Roux’s work. He began showing up at Butler’s office and Roux’s lab to talk about his plan and prove that he was serious.

“Eventually, I guess through enthusiasm, everyone finally was like ‘All right, we will listen to you,’” Hiebert said.

Months before Hiebert’s entrepreneurial epiphany, a company approached Roux about commercializing the same discoveries. The group wrote a grant proposal, vetted it through a biotech firm, and received approval from necessary parties. But at the last minute, the company canceled the deal.

Roux proposed that Hiebert pick up where it left off. Hiebert went home and told his father about the plan.

“As I gained leverage on one side of the table, I would go back and use that,” Hiebert said. “’Well, Dr. Roux thinks this is worthwhile, and he is this amazing scientist. I am not the only one that thinks this is worth a shot.’ And my dad would say, ‘Oh, this does sound interesting. Maybe we are interested.’ Then I would go back [to Dr. Roux] and say, ‘I’ve got real business people who think this is real interesting.’”

Hiebert legitimized the process with the first transaction: $20,000 to reimburse the university for the filing costs and legal fees of the three patents to which CottonGen has exclusive rights. In the agreement, the University of Texas holds 10 percent ownership of CottonGen and its future profits. Under UT’s Board of Regents rules, Roux could receive half the revenues the University receives on licensing the invention.

“It was a seminal moment in the negotiations with the university because we were handing over a substantial amount of money and saying, ‘Hey, we are serious about this. Here you go,’” Hiebert said.

The UT Office of Technology Commercialization has received 525 patents in the United States and worldwide, signed more than 275 licenses in the past 10 years and created more than 60 startup companies, according to the Office of Technology Commercialization.

The Crucial Greenhouse Stage

The crucial moment in the process is the greenhouse stage, when researchers know if the plants will grow and what, if any, traits they express. Roux and Hiebert acknowledged their interest in increased fiber length and thickness, but there are a few other potential traits. More important, Roux thinks this might be a more basic discovery than just the alteration of cotton plants, but of all plants.

Roux discovered that the enzyme that controls the regulation of growth can also regulate the opening and closing of a plant’s pores, called stomata. According to Mike Salvucci, research plant physiologist at the U.S. Department of Agriculture, regulating stomata can help a plant’s resistance to heat stress, one of the main limits of the agriculture industry in Texas.

“When you are in a hot, dry climate like Texas or Arizona, what happens is, when you start losing water from the surface of anything, you get a cooling effect called evaporative cooling,” Salvucci said in a phone interview. “If you can regulate stomata closure, you could potentially affect the level of heat on the plant, because the plant is also absorbing light and is heating up as a result.”

If a cotton plant rises above 93 degrees Fahrenheit, photosynthesis slows, and the plant begins to shut down. Under this heat stress, the cotton plant will produce shorter fibers and fewer cotton bowls, Salvucci said.

Roux found that the transgenic Arabidopsis also showed increased phosphate uptake. Phosphate, according to Roux, will be a limiting factor for fertilizer in the future. A plant stops growing once it consumes all of its phosphate.

Arabidopsis is Roux’s model system, and cotton is his first foray in a commercially valuable crop. He believes that if he can show increased phosphate uptake in cotton, the same concept should be applicable to any other crop.

“If that has any indication, for example, if we do see better phosphate utilization in cotton … hey man: tomato, potato, corn, you name it,” Roux said.

After the traits of the plants are recorded, Roux will collect the seeds and begin field trials on a South Texas cotton farm. Roux expects to complete preliminary field trials within two years.

From there, Hiebert and CottonGen will act as a technical provider to the six major companies that dominate the proprietary seed market. CottonGen will offer the companies an option to either buy a license to the product or an exclusive right that excludes competitors’ use. From the moment the trait is sold, it will take about five years before the product is commercialized and in stores, according to Hiebert.

Hiebert and CottonGen will not know if they have a valuable product until at least October – more than two years after the first investment – and may not see profits for as many as two to seven years, according to Hiebert.

“There’s a big question mark in there, but there’s a lot of money wrapped up in this,” Hiebert said. “Even a small market share really translates into a big profit for the investment that we’re looking for.”

Butler of the IC2 institute referred to Hiebert as “the next Michael Dell.” He added that CottonGen “will probably be a multimillion-dollar enterprise soon.”

Gaylon Morgan, a cotton specialist at Texas A&M University, said in an email that field trials will be needed before the benefits of CottonGen’s seeds are credible.

“If Dr. Roux’s patented process can improve cotton fiber length without sacrificing other important fiber qualities [such as strength and uniformity], it will be beneficial to the U.S. cotton producers and cotton fiber industry,” Morgan said. “We currently export over 75 percent of the cotton grown in the U.S., and the cotton mills require high quality cotton.”